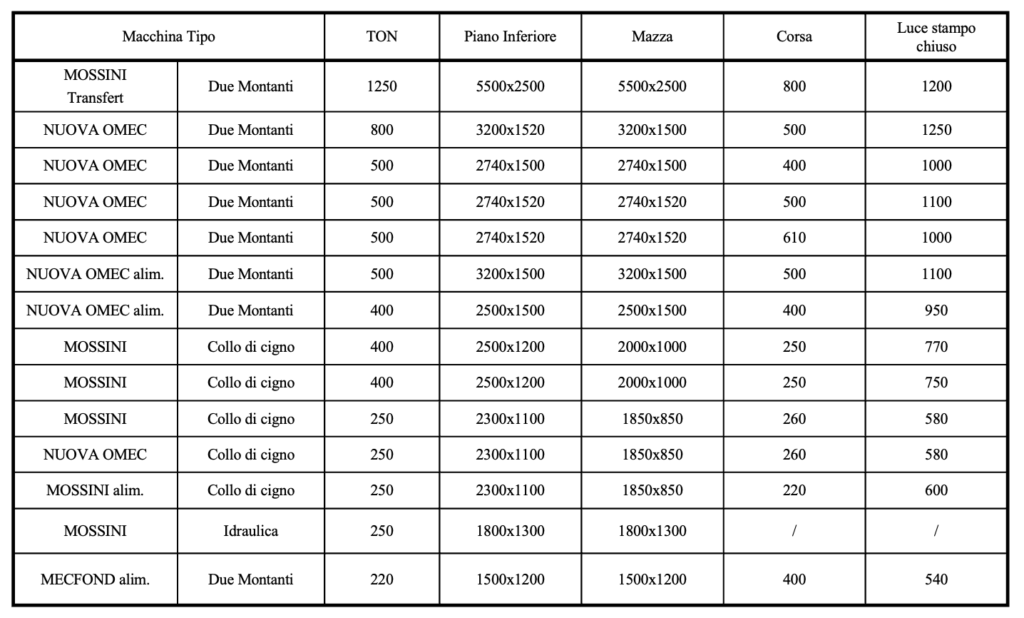

Transfert

Mossini 1250 Ton press is an example of advanced technology in action. Equipped with an electronic transfer, these presses have:

- Full automation: Automatic transfer of workpieces between the various machining stages.

- High precision: Thanks to electronic motion control, we guarantee millimetre accuracy.

- Production efficiency: Reduced downtime and increased productivity.

Fed by belt max. 1800 mm.

Table size 5500 x 2500 mm. Stroke 800 mm.

Mould light when closed 1200 mm.

Features Electronic transfer:

– Feed stroke – 0 – 1100 mm.

– Opening stroke – 0 – 250 mm.

– Lifting stroke – 0 – 200 mm.

– Min. distance from closed bars – 1000 mm.

– Max. distance between open bars – 2600 mm.

– H bars from the mould table – 700 mm.

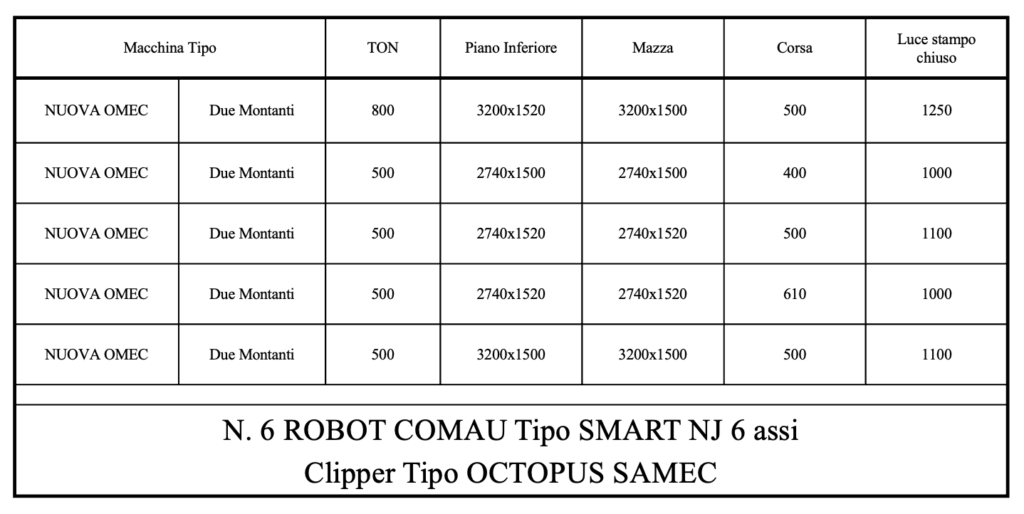

Robotized Line

The line is equipped with N 5 machines from 800 to 500 T, capable of performing stamping operations on sheets of different sizes and thicknesses. The presses are supported by 6 COMAU robots of the latest generation with automation systems that guarantee fast and precise production.

Square Cut Line

Starting from coil we are able to cut, notch, drill and stamp a sheet of sheet metal Here are some technical specifications of the presses we use:

Stamping Department Machines

In our stamping department, we have a wide range of machines, each with detailed technical specifications:

- Mechanical presses: Different tonnage capacities, from 1250 Ton to 40 Ton, to suit various types of processing.

- Hydraulic presses: For operations requiring constant, controlled force.

- Cutting and punching presses: Precise machines for finishing sheet metal.

Assembling

For assembly operations, LMS has automated workstations that offer:

- Efficiency and speed: Fast and accurate assembly of electrical and mechanical components.

- Quality control: Every step of the process is monitored to ensure compliance with quality standards.

Line of No. 30 TRE.CI and TECNA 45 to 60 kva punching posts equipped with modern machine parameter adjustment and control systems,

No. 10 100 kva punching machines with inverter technology TECNA – TRE.CI

Thickening machines for forming braids

No. 2 20 ton presses for bimetal forming and bending

- Manual lines for poly assembly

- Testing room for testing and calibration of poles

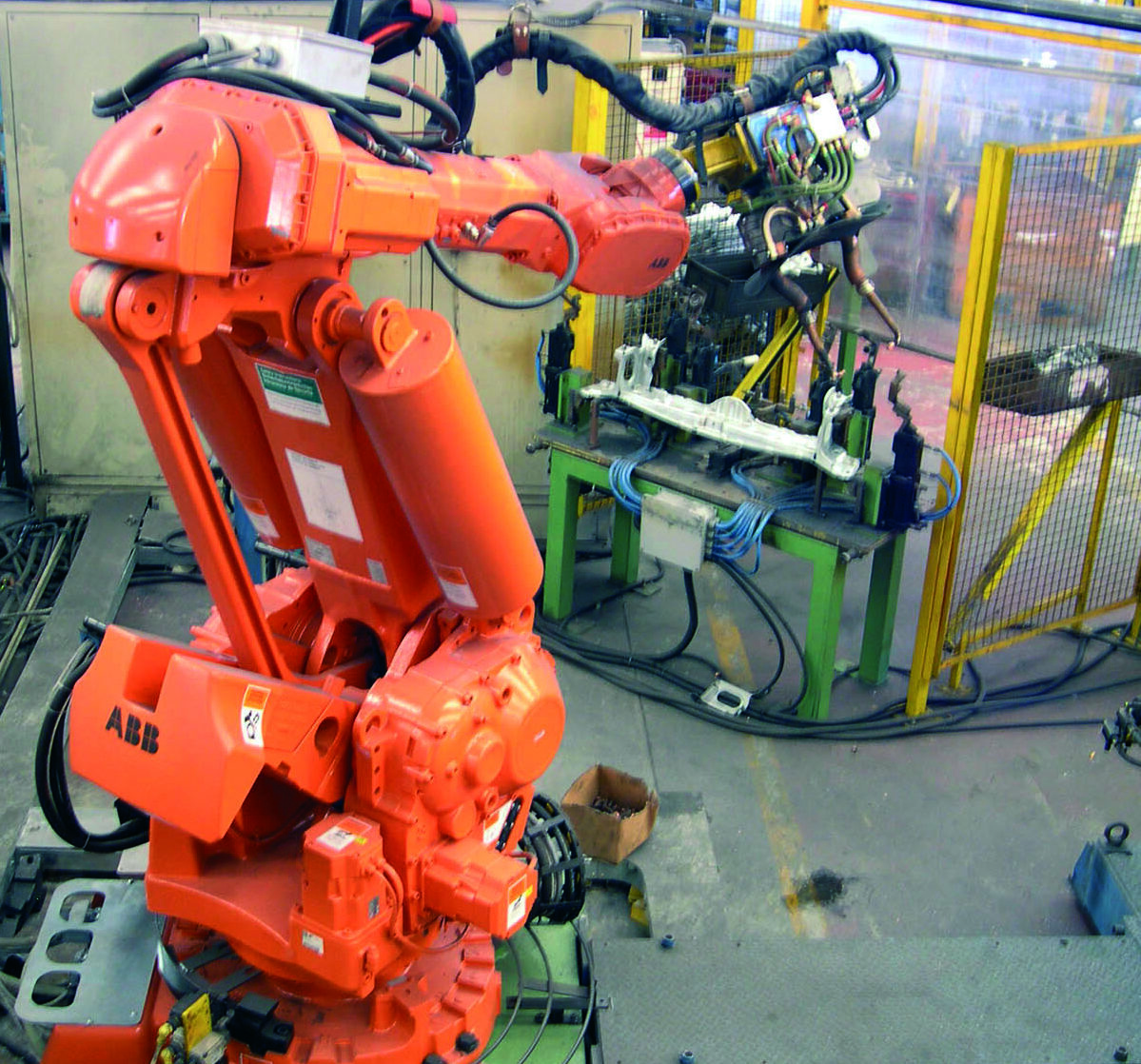

Slaughter/Robot

Our sheet metal department is equipped with state-of-the-art welding robots, which ensure:

- Automated welding: Precision and uniformity in every welded joint.

- Projection welding line: Ideal for welding small and medium-sized components, guaranteeing robustness and reliability.

- 6-axis robots for spot and wire welding for the assembly of moulded parts.

- ABB – COMAU – KUKA

- Projection welding machines from 45 kva to 125 kva.

- Semi-automatic dedicated assembly stations

- Continuous wire welding machines

Equipment

Our tool shop is equipped with high-precision machines for the manufacture and maintenance of tools:

- Lathes and milling machines: For precision machining of various materials.

- Grinding: For high precision machining and a high degree of finish.

- Wire EDM: For accurate cuts on conductive materials

For routine mould maintenance, we have an in-house tool shop equipped with:

- AgieCharmilles CUT E350 wire EDM

- Parallel lathe

- Milling machine with visualiser Table 1500×340

- Milling machine with visualiser Table 1000×250

- Tangential grinding machine Table 1000 x 350

- Benchtop drill, Radial drill

- Hardening furnace

Metrological Room

To guarantee the quality of our products, LMS uses advanced testing tools:

- POLI measuring machine mod. Antares: For high-precision three-dimensional measurements.

- Material Testing Machine: For testing the strength and mechanical properties of the materials used.

- Hexagon measuring machine

Measuring Range X = 2000 – Y = 1500 – Z = 1000 - Lonos Traction Test Machine

We are committed to providing fast turnaround times and efficient modes of operation to meet our customers' needs.

Thanks to our in-house organisation and advanced production capacity, we are able to handle both small and large orders, respecting the delivery times requested by the customer at the quotation stage.